Understanding Liquid Packaging Machines

What Are Liquid Packaging Machines?

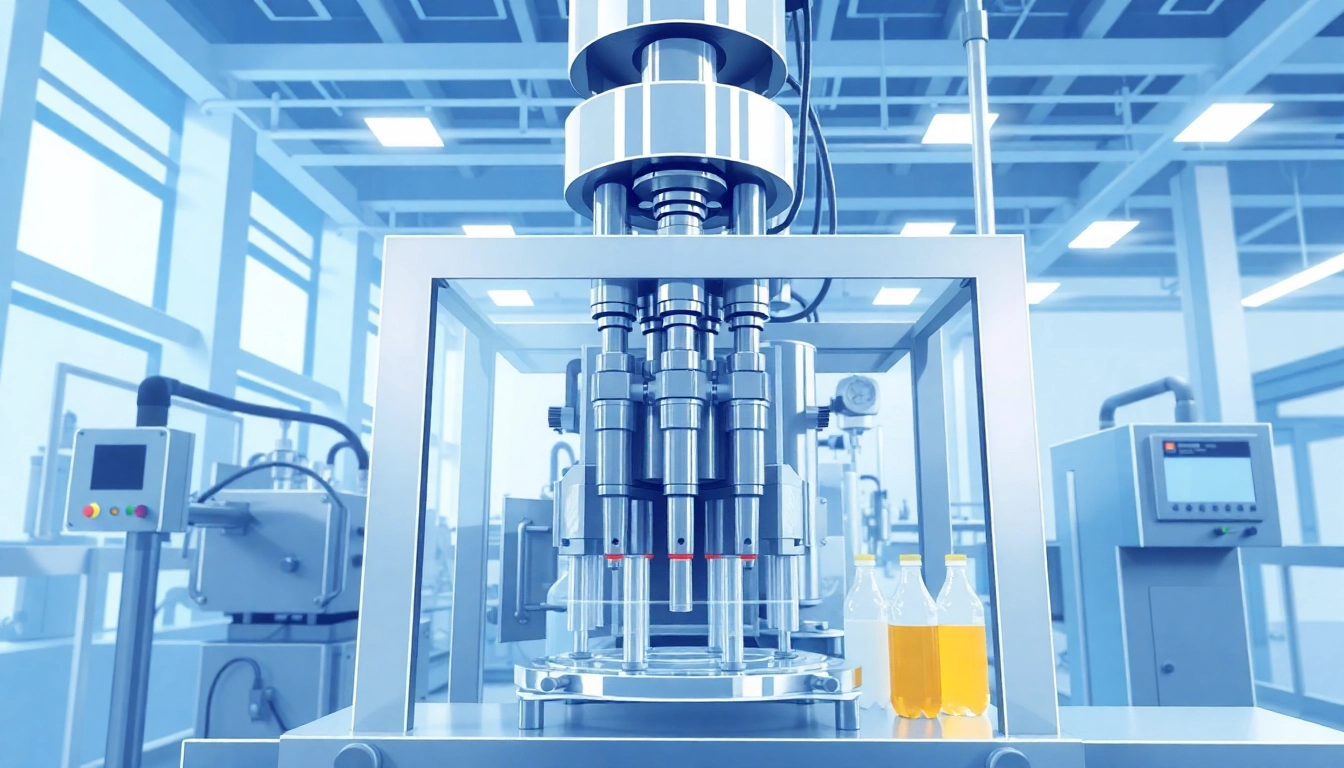

Liquid packaging machines are essential tools for industries that require the efficient packaging of liquid products. These machines are designed to fill, seal, and package liquids in various container types ranging from bottles to pouches. Their automation capabilities allow for high-speed operations that are critical in today’s fast-paced production environments. As a supplier of liquid packaging machines, it is essential to understand their functionalities and the significant role they play in streamlining business operations. Choosing the right Liquid Packaging Machine Supplier can enhance production capacity, quality control, and consistency across various products.

Common Types of Liquid Packaging Machines

The diversity of liquid packaging machines corresponds to the variety of liquid products available in various industries. Here are some common types:

- Filling Machines: These machines are responsible for filling containers with liquids. They can be further categorized by the filling mechanism they use, such as piston fillers, gravity fillers, and vacuum fillers.

- Capping Machines: These machines are used to seal filled containers with caps. They ensure that products are properly sealed to maintain freshness and prevent contamination.

- Labeling Machines: These devices apply labels to containers, providing essential product information and enhancing branding.

- Wrapping Machines: These machines wrap containers in plastic or other materials for added protection during shipping and storage.

- Combining Systems: Some machines are designed to perform multiple functions, such as filling, capping, and labeling in one integrated system.

Key Industries Using Liquid Packaging Solutions

Liquid packaging machines serve a range of industries by providing tailored solutions to meet their specific needs. The key industries include:

- Food and Beverage: This industry utilizes liquid packaging machines for juices, sauces, syrups, and dairy products to ensure safety and maintain quality during storage and transportation.

- Pharmaceuticals: Packaging in this sector requires strict compliance with health regulations. Liquid packaging machines allow for precision filling and secure closures to prevent contamination.

- Chemicals: Industrial liquids, including solvents and adhesives, need robust packaging solutions capable of handling corrosive materials safely.

- Cosmetics: The beauty industry uses liquid packaging for perfumes, lotions, and shampoos, ensuring products are attractively presented and sealed properly.

Benefits of Choosing the Right Supplier

Impact on Production Efficiency

Selecting an appropriate supplier of liquid packaging machines ensures that businesses can optimize their production efficiency. A reliable supplier offers machines that are not only compatible with specific production line requirements but also come equipped with advanced technology that minimizes downtime and boosts productivity. For instance, automation features can significantly reduce the manual labor involved in packaging processes, which not only enhances speed but also allows for continuous production cycles.

Cost-Effectiveness and Long-Term Value

Investing in high-quality liquid packaging machines from reputable suppliers represents a long-term value investment. While the initial costs may be higher, the benefits in terms of reduced operational costs, decreased waste, and extended machine lifespan can lead to substantial long-term savings. Moreover, suppliers that provide comprehensive warranty and service options can help mitigate maintenance costs down the line, further enhancing the overall value of the investment.

Custom Solutions for Unique Needs

Every business has unique packaging needs based on the products they produce. A good liquid packaging machine supplier will offer customizable solutions that align with specific operational requirements. Custom solutions can include bespoke machine designs that accommodate unusual container shapes or sizes, specific filling capacities, and specialized sealing mechanisms. This personalization ensures that businesses can achieve maximum efficiency and product integrity during the packaging process.

Features to Consider When Selecting a Machine

Machine Automation and Technology

The level of automation in a liquid packaging machine substantially impacts its operational efficiency. Modern machines come equipped with state-of-the-art technology, including sensors and programmable logic controllers (PLCs) that enhance precision and reduce human error. When selecting equipment, businesses should consider the technology used in the machines, as well as the ability to integrate with existing production systems. Automation can range from simple manual operations to fully automatic systems that require minimal operator intervention.

Capacity and Scalability

Understanding production needs is critical when selecting a liquid packaging machine. This includes knowing the expected output volumes and the types of liquids being packaged. Machines should have the capacity to handle current production volumes while providing the scalability necessary to accommodate future growth. Suppliers should offer machines with adjustable settings for different product types and package sizes without the need for additional machinery.

Maintenance and Support Services

Reliable maintenance and support are essential to maximizing the longevity and performance of liquid packaging machines. When evaluating suppliers, businesses should assess the level of customer support offered, including training resources, parts availability, and technical support. A strong partnership with suppliers can reduce the risk of prolonged downtime and ensure that any operational issues are resolved quickly and efficiently.

Case Studies of Successful Implementations

Food and Beverage Industry Success

A leading juice manufacturer faced challenges with manual filling lines that led to inconsistent fill levels and labor inefficiencies. By investing in an automated liquid filling machine from a specialized supplier, the company was able to reduce labor costs by 30% while increasing output by over 50%. The solution included customized settings to cater to their various juice types, resulting in improved quality control and minimal product waste.

Pharmaceutical Packaging Innovations

A pharmaceutical company sought to enhance its packaging process to meet strict regulatory requirements while improving efficiency. Partnering with a renowned liquid packaging machine supplier, they implemented a fully automated filling and sealing system that kept their production line compliant with health standards. This innovative solution resulted in a 60% reduction in manual handling mistakes and improved overall product traceability.

Case Study: Small Batch vs. Mass Production

Another case involved a cosmetics manufacturer that transitioned from small batch production to mass production. With aspirations to grow its market share, the company leveraged the services of a liquid packaging machine supplier to develop a scalable system. The newly implemented machinery not only handled larger volumes but also had the flexibility to switch between different product lines effectively. This move not only resulted in reduced packaging time but also allowed for more complex production runs that increased customer satisfaction and repeat sales.

The Future of Liquid Packaging Solutions

Emerging Technologies in Packaging

The liquid packaging industry is on the brink of significant changes driven by technological advancements. For example, smart packaging technologies are being integrated into liquid packaging solutions. These innovations allow companies to monitor product quality and freshness continuously. As the industry moves towards Industry 4.0, automation, artificial intelligence, and the Internet of Things (IoT) are becoming imperative in optimizing production and logistics processes. Suppliers that incorporate these technologies into their offerings position themselves as leaders in the evolving packaging landscape.

Sustainability Trends in Packaging Machinery

With an increasing focus on environmental responsibility, sustainability is becoming a central pillar in the development of liquid packaging machinery. Manufacturers are adopting eco-friendly practices by utilizing materials that reduce waste, energy-efficient machines, and packaging solutions designed for recyclability. Choosing a liquid packaging machine supplier that prioritizes sustainable practices not only enhances a company’s green credentials but can also appeal to a growing base of environmentally conscious consumers.

Preparing for Industry Changes and Challenges

The liquid packaging market is continuously evolving, influenced by changing consumer preferences and regulatory requirements. Companies need to remain agile to adapt to these changes effectively. This entails collaborating with suppliers who can provide timely insights into trends and innovations, as well as flexible solutions that can accommodate changes in production demands. Continuous training and education about new technologies will also be vital for businesses aiming to stay competitive in the fast-evolving beverage, food, pharmaceutical, and cosmetics sectors.