What Are Electromagnetic Shielding Materials?

Definition and Importance

Electromagnetic shielding materials are specialized materials designed to block or attenuate electromagnetic fields. Their primary purpose is to protect sensitive electronic equipment from interference caused by electromagnetic interference (EMI) and radio frequency interference (RFI). As our reliance on electronics and wireless communication systems grows, so does the importance of effective shielding solutions.

Effective electromagnetic shielding materials embrace a variety of physical properties, including electrical conductivity, magnetic permeability, and material thickness. These factors contribute to the material’s ability to prevent electromagnetic waves from penetrating, thus maintaining signal integrity and equipment reliability.

Common Applications in Industry

Electromagnetic shielding is vital across various industries, including telecommunications, automotive, aerospace, and medical devices. In telecommunications, for example, shielding is used to protect smartphones and base stations from external EMI to ensure clear signal transmission. In the medical field, equipment like MRI machines and diagnostic devices rely on precise shielding to prevent interference from nearby electronics, which could lead to inaccurate readings.

Additionally, in the automotive industry, shielding materials help protect sensitive components in electric vehicles from radio frequency interference, promoting safety and performance. Additionally, aerospace applications often utilize advanced shielding solutions to ensure communication systems remain operational in challenging environments.

Electromagnetic Interference Explained

Electromagnetic interference (EMI) refers to unwanted disturbances generated by external sources that affect the operation of electronic devices. These disturbances can originate from various sources, including power lines, radio transmitters, and even natural phenomena like lightning. EMI can cause issues ranging from minor performance degradation to complete system failures.

The challenges posed by EMI drive the need for materials that can effectively mitigate its effects, leading to the development of innovative shielding technologies. Understanding EMI and its sources is critical as it aids in selecting the most appropriate shielding solutions for different applications.

Types of Electromagnetic Shielding Materials

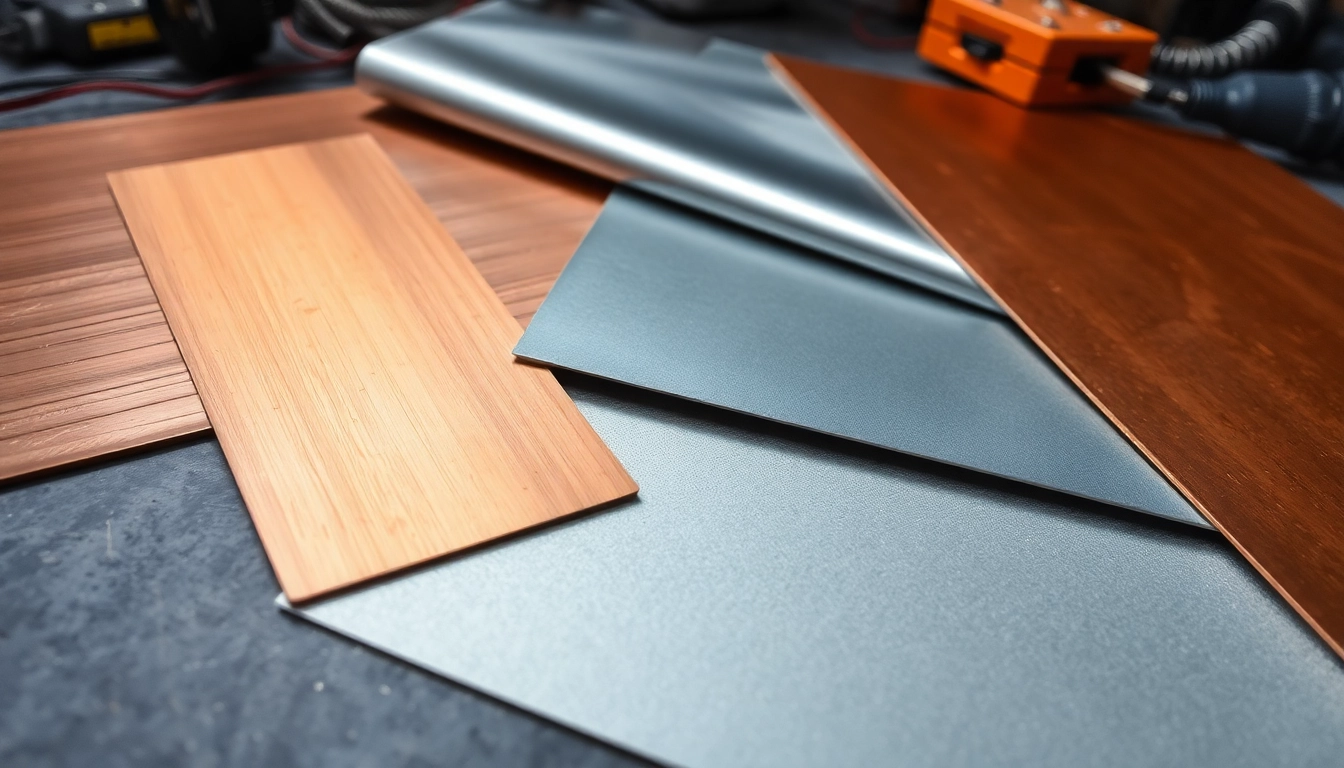

Metal Materials: The Backbone of Shielding

Metals have long been considered the cornerstone of EMI shielding materials due to their excellent electrical and thermal conductivity. Commonly used metals in shielding applications include:

- Copper: Known for its superior conductivity and effectiveness in attenuating both electric and magnetic fields. It is often used in applications requiring high-frequency shielding.

- Aluminum: Lightweight and resistant to corrosion, aluminum is suitable for various applications, particularly in the aerospace sector.

- Steel: Often used in enclosure designs, steel offers exceptional strength and durability, making it ideal for industrial applications.

- Nichrome: This alloy retains its strength at high temperatures, making it useful for applications where thermal conditions can become extreme.

Each metal has its unique properties and applications, making the selection process dependent on specific use cases and performance requirements.

Conductive Polymers and Their Benefits

Conductive polymers are another category of materials employed in electromagnetic shielding. Unlike traditional metals, conductive polymers offer lightweight and flexible alternatives that can easily be integrated into various devices. Some of the advantages of conductive polymers include:

- Flexibility: Conductive polymers can be manipulated into different shapes and sizes, making them suitable for applications requiring a custom fit.

- Lower weight: Comparing to metals, conductive polymers significantly reduce weight without sacrificing performance, which is beneficial for portable devices.

- Corrosion resistance: Many conductive polymers resist corrosion, thereby enhancing the longevity of the products in which they are used.

Advanced developments in conductive polymers are leading to their increasing adoption in applications like smartphones, wearables, and medical devices.

Composite Materials for Enhanced Performance

Composite materials, which combine different substances to harness their superior characteristics, are also seeing extensive use in the field of electromagnetic shielding. These composites often blend metals, polymers, and ceramics to achieve enhanced shielding effectiveness, improved flexibility, and reduced weight. Typical examples include:

- Metal Matrix Composites: These feature a metal matrix reinforced with other materials, resulting in improved mechanical properties and shielding performance.

- Hybrid Composites: This type involves combining conductive polymers with metal fillers, resulting in materials that exhibit both flexibility and high conductivity.

- Graphene Composites: Recognized for their remarkable electrical properties, graphene composites are being explored in advanced shielding solutions, especially in high-frequency applications.

The versatility of composite materials positions them as a significant player in the future of electromagnetic shielding, particularly in compact devices and cutting-edge technology.

Choosing the Right Electromagnetic Shielding Material

Factors to Consider: Conductivity and Thickness

When selecting the appropriate electromagnetic shielding material, several critical factors should be considered:

- Conductivity: The material’s ability to conduct electricity directly affects its shielding effectiveness. Materials with higher conductivity typically offer better EMI attenuation.

- Thickness: The thickness of the shielding material influences its performance. Generally, thicker materials provide greater attenuation, but the added weight may be a concern for some applications.

- Frequency Range: Different materials perform better at specific frequency ranges, so choosing one that aligns with the operational frequency of the equipment is crucial.

Cost Versus Performance Analysis

The balance between cost and performance is always a consideration in material selection. While high-performance materials such as copper may offer superior shielding capabilities, they can also be more expensive. It is essential to conduct a cost-benefit analysis to determine whether the increased cost aligns with the benefits for specific applications. Often, a mid-range option that meets performance requirements without excessive costs may be the most practical choice.

Environmental Impact and Safety

Considering environmental impacts and safety is increasingly critical in material selection. Factors such as recyclability, toxicity, and potential health risks associated with certain materials should be weighed in the decision-making process. Many manufacturers today are seeking eco-friendly alternatives to traditional materials while ensuring they meet the necessary performance specifications.

Best Practices for Using Shielding Materials

Installation Techniques for Maximum Effectiveness

Proper installation of shielding materials is fundamental for achieving the desired performance. Best practices include:

- Surface Preparation: Ensure that surfaces are clean and smooth to facilitate proper adhesion and contact between the shielding material and the substrate.

- Overlap and Seam Sealing: Overlapping shielded material edges and using conductive adhesives can help prevent leakage of electromagnetic fields.

- Grounding: Proper grounding of shielding materials can enhance effectiveness by redirecting EMI to the ground rather than allowing it to interfere with devices.

Maintenance of Shielding Materials

Routine maintenance is essential to ensure the longevity and effectiveness of shielding materials. Factors to consider include:

- Regular Inspections: Conducting periodic inspections can detect early signs of wear or damage that could compromise shielding integrity.

- Cleaning Protocols: Specific cleaning techniques suitable for the material type should be applied to avoid damaging the shielding effectiveness.

Regulatory Standards and Compliance

Compliance with local and international regulations regarding electromagnetic shielding is vital for manufacturers. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provide standards that must be adhered to. Understanding and meeting these requirements contribute to product safety, reliability, and marketability.

Future Trends in Electromagnetic Shielding Technologies

Innovations in Material Science

The field of electromagnetic shielding is undergoing significant advancements in material science. Researchers are exploring nanomaterials, metamaterials, and other innovative technologies that could revolutionize how we approach shielding challenges. For instance, nanocomposites are being engineered to combine superior conductivity with light weight, opening doors for new applications across electronics and communications.

Integration with Modern Electronics

As electronics become more compact and complex, the integration of shielding within the design phase is becoming increasingly important. Shielding solutions now need to be embedded or integrated into the device itself rather than applied as an overlay. This trend is particularly relevant in the wearables and IoT devices, where space is limited, and functionality is non-negotiable.

The Role of Smart Materials in Shielding

Smart materials, which can change their properties in response to environmental stimuli, will likely play a pivotal role in future shielding technologies. These materials could be engineered to provide adaptive shielding, dynamically optimizing their performance based on the surrounding electromagnetic environment. Such innovations could lead to significant breakthroughs in how we protect sensitive electronics from EMI and RFI.