Understanding Needle Guns and Their Applications

What is a Needle Gun?

A needle gun, also known as a needle scaler or needlegun scaler, is a specialized power tool designed primarily for surface preparation tasks. Utilizing a series of high-speed needles, the needle gun effectively removes unwanted materials such as rust, paint, mill scale, and other contaminants from metal surfaces. The tool operates either through pneumatic (air-driven) or electric motors, making it a versatile option for various applications.

This powerful tool can be particularly beneficial in areas such as construction, shipbuilding, and automotive repairs, where maintaining the quality and safety of metal surfaces is paramount. For instance, the needle gun is widely regarded for its effectiveness in achieving detailed surface cleaning without damaging the underlying material.

Common Uses of Needle Guns in Various Industries

Needle guns find applications across multiple industries, further emphasizing their versatility and efficacy. Some of the key sectors utilizing needle guns include:

- Shipbuilding and Repair: In maritime industries, needle guns remove rust and old paint from ship hulls, enhancing longevity and performance.

- Manufacturing: Factories employ needle guns for cleaning metal parts prior to welding or painting, ensuring strong bonds and finishes.

- Automotive: In automotive repair shops, needle guns are used for cleaning chassis and components, effectively preparing surfaces for coating or reassembly.

- Construction: Builders use needle guns to prepare steel beams and reinforcements for various structural applications, ensuring they are free from contaminants.

- Aerospace: The aerospace sector relies on needle guns to clean metal fasteners and components while ensuring precision and safety in high-stakes environments.

Advantages Over Traditional Cleaning Methods

Needle guns offer several advantages compared to traditional cleaning methods such as sandblasting, scrapers, or chemical solvents:

- Efficiency: The high-speed operation and needle design allow for rapid removal of materials compared to manual techniques.

- Surface Integrity: As needle guns operate without abrasive materials, they minimize the risk of damaging the underlying surface, maintaining structural integrity.

- Flexibility: Needle guns can be used on irregular or contoured surfaces, making them suitable for a wide range of applications.

- Less Cleanup: The cleanliness and effectiveness of needle guns result in less debris creation, reducing post-cleaning cleanup efforts.

- Usage Versatility: A variety of needle types can be used for different applications, optimizing results across various materials and conditions.

Choosing the Right Needle Gun for Your Needs

Factors to Consider When Selecting a Needle Gun

Choosing the right needle gun involves considering its specifications and the needs of your specific application:

- Power Source: Determine whether an electric or pneumatic needle gun best suits your workspace. Pneumatic options offer greater power but require an air compressor, whereas electric models may provide easier portability.

- Needle Configuration: The number and length of needles can significantly affect performance. Higher needle counts can remove material quicker, while longer needles help reach into tight spaces.

- Weight and Size: Ergonomics matter. A lighter, well-balanced tool can reduce user fatigue during prolonged use.

- Noise Levels: Consider the noise output, especially in environments where sound restrictions exist or where ear protection is mandated.

- Maintenance Requirements: Assess how easy it is to maintain the tool, as well as the availability of replacement parts.

Comparing Electric vs Pneumatic Needle Guns

When deciding between electric and pneumatic needle guns, it’s crucial to evaluate the pros and cons each offers:

| Feature | Electric Needle Guns | Pneumatic Needle Guns |

|---|---|---|

| Power Source | Electricity | Compressed air |

| Portability | Highly portable, no air compressor needed | Less portable, requires an air compressor |

| Power | Generally lower power | Higher power and efficiency |

| Noise Level | Typically quieter | Can be noisier due to compressor operation |

| Maintenance | Relatively low maintenance | Requires regular compressor maintenance |

Ultimately, the best choice depends on specific needs. Electric needle guns may be preferable for small, general-purpose tasks, while pneumatic models suit heavy-duty applications.

Popular Brands and Models to Explore

Several reputable manufacturers produce needle guns that cater to different needs and budgets. Below is a selection of popular brands and models:

- Ingersoll Rand: Known for reliability and performance, they offer various electric and pneumatic needle scaler options.

- Husky: Their needle guns are budget-friendly, making them ideal for DIY enthusiasts and smaller projects.

- Chicago Pneumatic: A prominent name in pneumatic tools, their heavy-duty scalers are built for contractors and industrial applications.

- Jet: Offers a range of powerful needle scalers, combining efficiency with user-friendly designs.

- Von Arx: A well-respected manufacturer for high-end needle guns, known for their precision and durability.

Operating a Needle Gun: Best Practices

Preparation Steps Before Use

Preparation is crucial for using a needle gun effectively and safely:

- Read the User Manual: Always consult the manufacturer’s manual to understand specific features and safety warnings.

- Wear Protective Gear: Use appropriate personal protective equipment (PPE), including goggles, gloves, and respiratory masks, to safeguard against dust and debris.

- Inspect the Tool: Before use, examine the needle gun for damage, ensuring that needles are securely attached and free from excessive wear.

- Prepare the Work Area: Clear the workspace of obstacles, ensuring ample space for movement and proper positioning of the air compressor if applicable.

- Connect Power/Supply: If using a pneumatic needle gun, ensure the air compressor is connected and set to the recommended pressure level.

Safety Tips When Using Needle Guns

Ensuring safety while operating needle guns is paramount. Keep the following safety tips in mind:

- Avoid Loose Clothing: Wear fitted garments to prevent snagging on the needle gun.

- Keep Hands Clear: Always keep your hands and any body parts away from the working end of the tool; use ergonomic grips to avoid accidental contact.

- Work in Well-Ventilated Areas: Ensure adequate ventilation if you are working indoors to reduce exposure to harmful dust and particles.

- Do Not Overreach: Maintain good balance and positioning while operating to prevent falls or accidents.

- Conduct a Break Test: Before actual use, perform a test run to ensure the needle gun is functioning correctly.

Techniques for Optimal Performance

To maximize efficiency and results when using a needle gun:

- Use the Right Needles: Select appropriate needles based on the material and type of contamination—longer needles for tight corners and shorter ones for larger flat surfaces.

- Maintain the Right Angle: Hold the needle gun at an angle of approximately 30 degrees to the surface for optimal impact force.

- Don’t Rush: Allow the tool to do the work; rushing can lead to uneven cleaning and increased wear on the tool.

- Regularly Check Needle Wear: Replace needles as they become worn to maintain performance and prevent damage to the surface being cleaned.

- Technique Variation: Rotate the tool slightly during operation to create an effective cleaning pattern and prevent overworking one area.

Maintenance of Needle Guns for Longevity

Essential Maintenance Practices

Like any power tool, needle guns require regular maintenance to ensure optimal performance and longevity:

- Clean After Every Use: Remove dirt and debris to maintain cleanliness and allow for better functionality during subsequent uses.

- Lubricate Moving Parts: Regularly apply lubricant to the internal mechanisms to prevent corrosion and wear.

- Inspect Needles Regularly: Check for bends or breaks; replace damaged needles to avoid inefficient operation.

- Store Properly: Keep the needle gun in a dry place to protect it from moisture, and use protective cases if needed.

- Regular Professional Checks: Consider sending the needle gun for professional checks periodically to ensure all components are functioning correctly.

Signs Your Needle Gun Needs Repair

Being aware of the signs that indicate your needle gun may require repair can save time and costs:

- Reduced Power: If the tool feels weaker than before or struggles to operate, this may indicate internal damage or air leaks.

- Excessive Vibration: If the needle gun vibrates more than usual, it could be a sign of misalignment or a problem with the needle attachments.

- Unusual Noises: Listen for clicking or grinding sounds during operation, as these can signify wear or failure of internal components.

- Air Leaks: Check for air leaks in pneumatic models as this can cause loss of pressure and reduce efficiency.

- Difficulty Starting or Stopping: If the tool does not start up or shut down smoothly, the electrical or mechanical components may need attention.

How to Store Your Needle Gun Properly

Proper storage prolongs the life of the needle gun. Here are some storage tips:

- Keep in a Dry Location: Store in a cool, dry environment free from moisture and high humidity.

- Avoid Extreme Temperatures: Avoid exposing the tool to extremely low or high temperatures which can deteriorate components.

- Secure the Cord: If your needle gun is electric, ensure that the power cord is not kinked or damaged during storage.

- Use Protective Cases: If available, store in a protective case to shield the tool from dust and accidental impacts.

- Check Periodically: Conduct occasional checks on the stored tool to ensure no damage occurred during storage.

Case Studies: Needle Guns in Action

Before and After: Surface Cleaning Results

Let’s illustrate the effectiveness of needle guns with a before-and-after analysis:

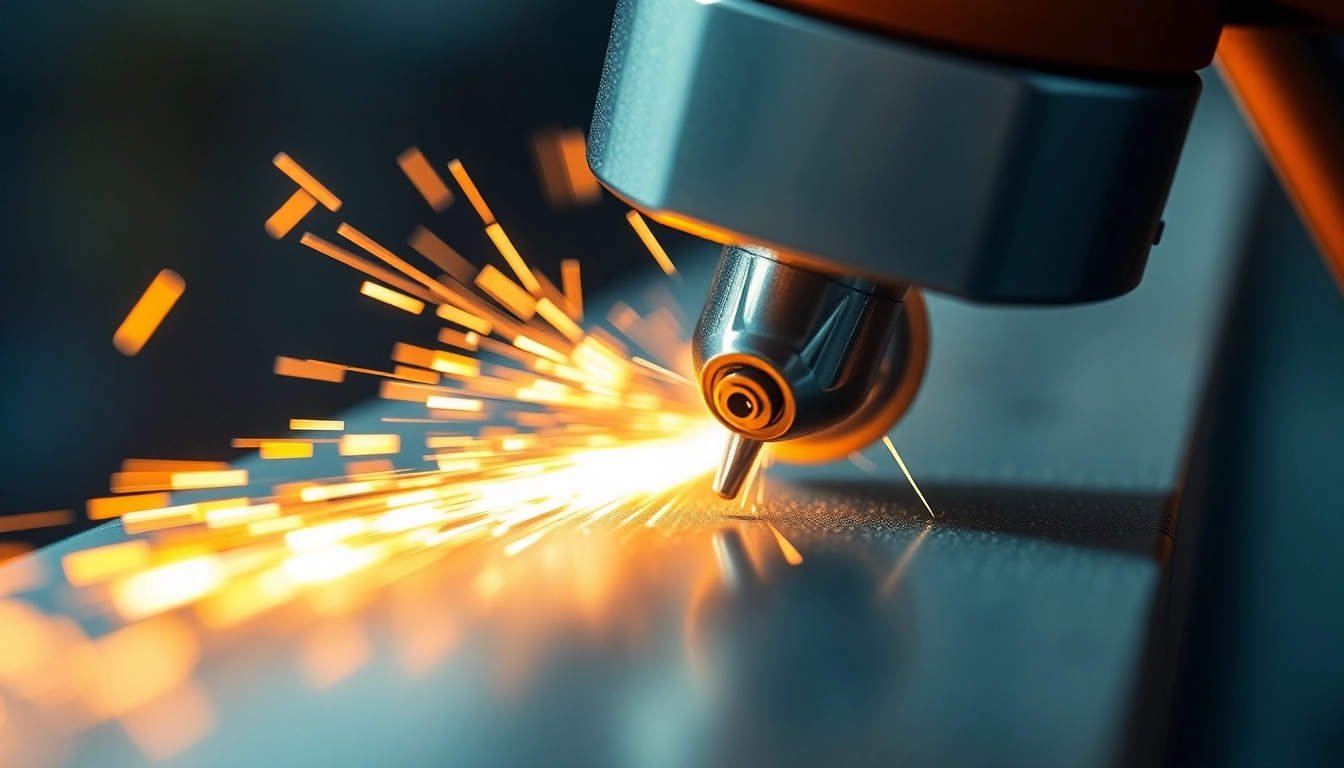

The above image demonstrates significant transformation, showcasing the removal of rust and old paint, thus highlighting how needle guns can restore surfaces and extend their life.

Project Case Study: Industrial Application

In a recent industrial setting, a mid-sized manufacturing facility faced ongoing issues with rust accumulation on their machinery. The company’s maintenance team decided to implement the use of needle guns. Over a span of three months, they employed needle guns across several machines, achieving:

- A 50% reduction in cleaning time compared to traditional methods.

- Substantial cost savings due to less downtime during maintenance.

- Significantly cleaner surfaces, which improved adherence for subsequent finishes.

This case emphasizes the value of investing in quality needle guns to enhance operational efficiency in industrial environments.

Customer Testimonials and Feedback

Here are a few testimonials from users who have employed needle guns across various applications:

“We switched to needle guns for our rust removal processes, and the difference has been remarkable. The time saved is incredible, and the surfaces have never looked better.” – John D., Maintenance Supervisor

“As an automotive technician, using the needle gun has expedited my workflow tremendously. I get cleaner results without compromising the underlying metal!” – Sarah P., Automotive Technician

“Our shipyard has adopted needle guns for hull treatments. The efficiency combined with the level of detail we achieve makes it a key tool in our arsenal.” – Robert H., Shipyard Foreman